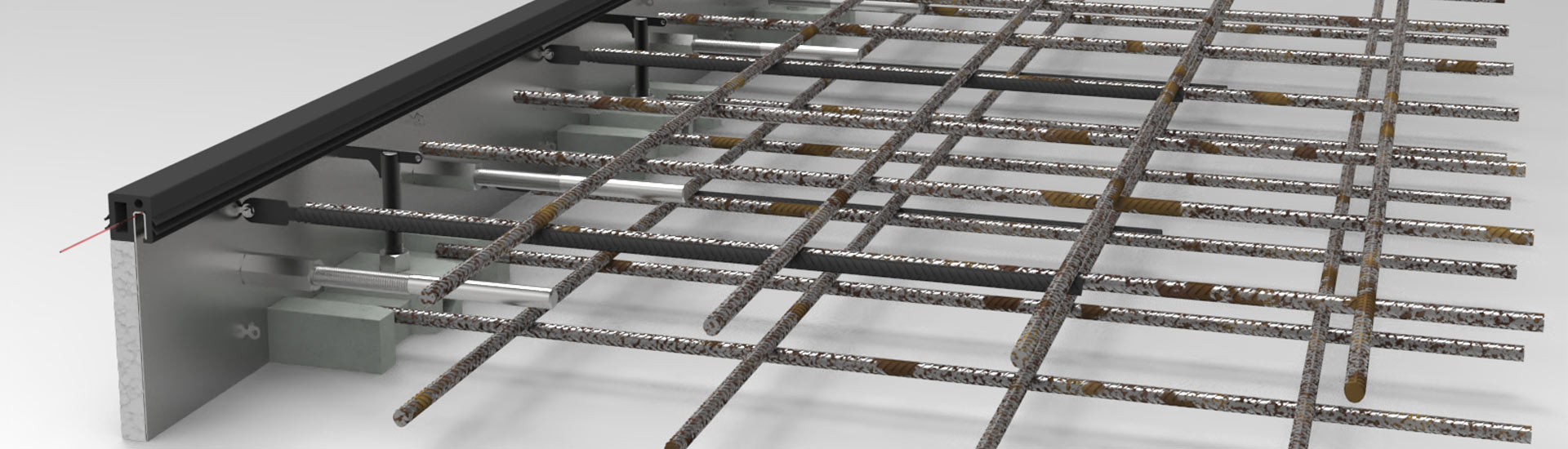

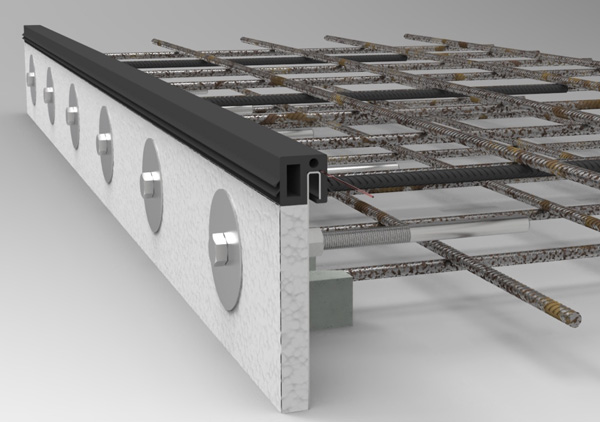

Concrete Expansion Joint System

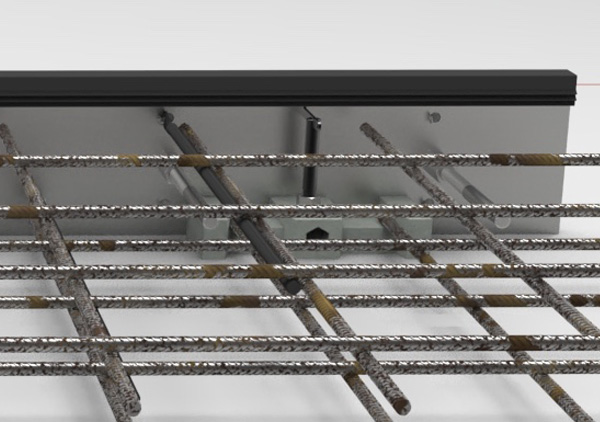

Various depths, Dowel Bar Spacing and Holes are avilable

Please contact us for a quote.

Permanent Shutter - NO stripping shutter.

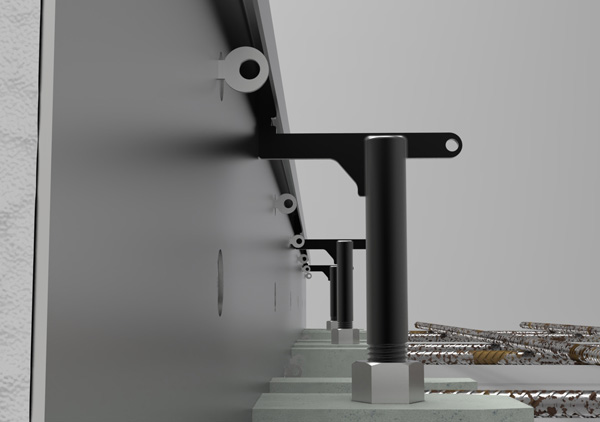

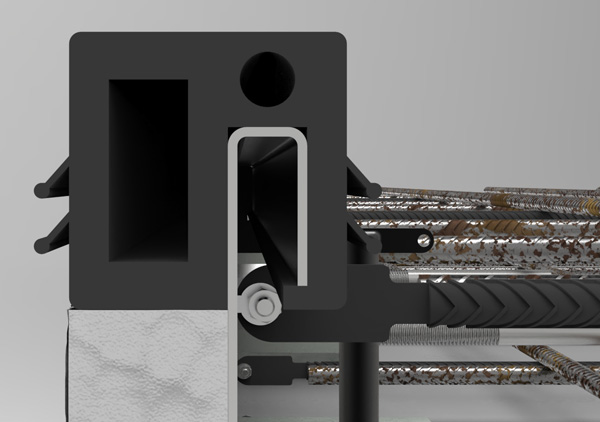

Precision Height set up - Adjustable to be millimetre perfect.

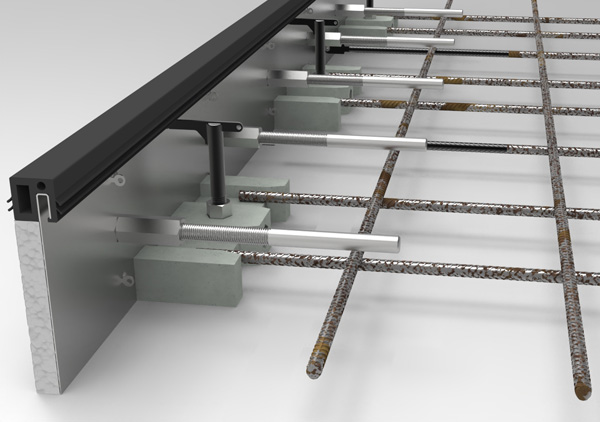

Joint Seal is Part of the Expansion - no going back to site to strip and seal joints.

No Polysulphide required.

Suitable for power screeds to run on.

OPTIONAL - Threaded Dowel Bars can be removed from the side of the Expansion which is not been poured to avoid trip Hazards - or a Continuous pour beyond the Expansion system is now possible. Steel fixing and pouring an entire area gives excellent economic advantages in particular for companies who use subcontractors or those working to a tight programme.

Acra Screed - GO Concrete Expansion Joint System

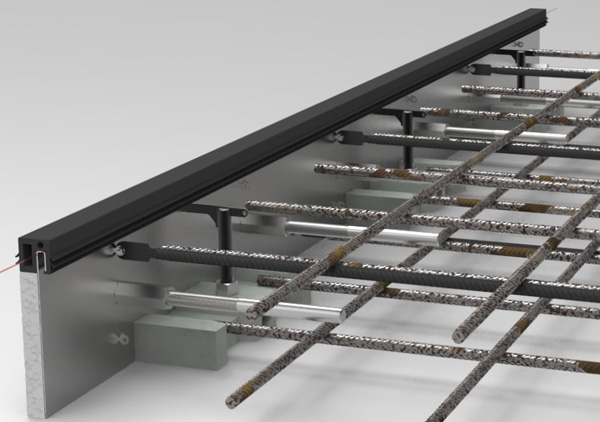

With the GO Expansion you get the permanent shutter, expansion foam the tie bars, and the expansion seal itself. With all other components such as Dowel Cradles and bars also available from Acra Screed.

The system has been designed by many years of onsite experience and a thorough understanding of on-site demands. You can prepare all the steel work in the slab and have the expansion in place ready for the concrete crew who can then carry out a continuous pour. You don't have to go back to site or wait for a dry day to fill the joint the benefits are multiple.

Better Quality - not only is the system better for you, it’s a much better finish for your customer because the seal is locked into the concrete and its innovative design allows movement in the joint.

For the seal itself we have teamed with NUFOX Rubber - Formed in 1981, the Manchester based company are at the forefront of their sector, through various acquisitions their in house experience dates back as far as 1933 making them true experts in the field.

Nufox presently serve – among others, the Construction, Aerospace, Defence, Marine, Rail and Oil & Gas sectors.

Debbie Garside – Sales Nufox Rubber

When Acra Screed approached us to manufacture their new expansion joint seal our team took careful consideration as to its application. Nufox recommended EPDM, because it has good weathering properties. Its resistance to UV and its durability in freezing temperatures makes this material the best choice when exposed to the elements.

This material is used for general industrial / commercial applications including: seals, Boat fenders, glazing sections, cable protectors, weighbridge rubber, wall guards and other high exposure miscellaneous sections. Excellent water/steam, weather properties; and good chemical resistance, although not advised for mineral oils, in which case we can provide a Neoprene or Nitrile seal.

Acra Screed - GO Concrete Expansion Joint System

Call now for more details +44 (0) 1729 840000

GO Expansion Specification PDF

|